POLCA: the right size in complex production environments

By Pascal Pollet – Sirris, Belgium

WIP, Work in Progress or Work in Process, stands for all the unfinished goods anywhere in a production process, between raw material and finished product. The more insight into WIP, the smoother the planning and production process.

In an earlier article, we discussed the many advantages of a limited amount of Work In Progress (WIP). Less WIP makes lead times in production shorter and more stable. Stable lead times make production more predictable, which in turn simplifies the planning work.

In this last article in the series we discuss, after Kanban and CONWIP, another smart card-based method for limiting WIP: POLCA.

POLCA: a simple method for complex environments

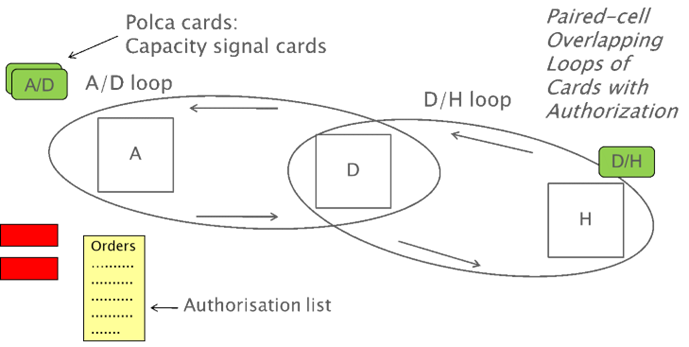

POLCA stands for Paired-Cell Overlapping Loops of Cards with Authorisation. POLCA is a management system for High-Mix, Low-Volume production environments and companies with custom-made products. The aim is to keep the lead times on the shop floor predictable and short.

When it is well-organised, POLCA controls the shop floor in these complicated environments highly effectively. The system has similarities to the Kanban system, which is itself better suited for environments with little product variety.

POLCA, push or pull?

To understand how POLCA works, we must first make a distinction between two types of production control systems, push and pull systems:

- A ‘push system’ releases a work order to the shopfloor on the basis of the scheduled start date. This scheduled start date is usually calculated by the planning system via ‘back scheduling’. A retroactive schedule is drawn up on the basis of the established lead times per operation step. The orders are, as it were, ‘pushed’ through the production process.

- A ‘pull system’, by contrast, releases work orders on the basis of the current status of the production system. If for example a subsequent work station is offline or is already overloaded, it makes no sense to start a new order that will have to wait. In such a case it is better to give priority to the orders for which capacity is available at the next work station. This ensures better use of resources and improves flow through the system.

The best of both worlds with POLCA

The POLCA system releases a production order to a work station on the basis of the combination of a push and a pull signal:

- Push signal: The planning authorises the release of a production order at a work station as of the authorisation date. This prevents orders being started unnecessarily early.

- Pull signal: POLCA controls this by means of an ingenious system in which cards circulate between overlapping loops. Two successive work stations in a routing form a loop together (the ellipses in Figure 1). A limited number of POLCA cards circulate in each loop.

POLCA cards and production loops

A POLCA card is in principle a capacity signal that indicates that there is processing capacity. A work order may only enter a loop if a card is available. As soon as an order comes into a loop, a card is attached to it. As soon as an order leaves a loop, the card is returned to the first station of that loop and kept on a POLCA board (Figure 3).

That card is then available for a subsequent order. The last station can always start and needs no card. At the intermediate stations (like D in figure 1) two cards are attached to the order: an A/D card and a D/H card. At the first and the last station only one card is attached.

Figure 1:Two overlapping POLCA loops with POLCA cards

A POLCA system is in fact a logical extension of the CONWIP system, which is in essence a POLCA system with only one card loop. CONWIP is an effective solution for environments with a mostly linear production flow, while POLCA is better suited to more complex production processes, with both converging and diverging material flows.

How does POLCA work in practice?

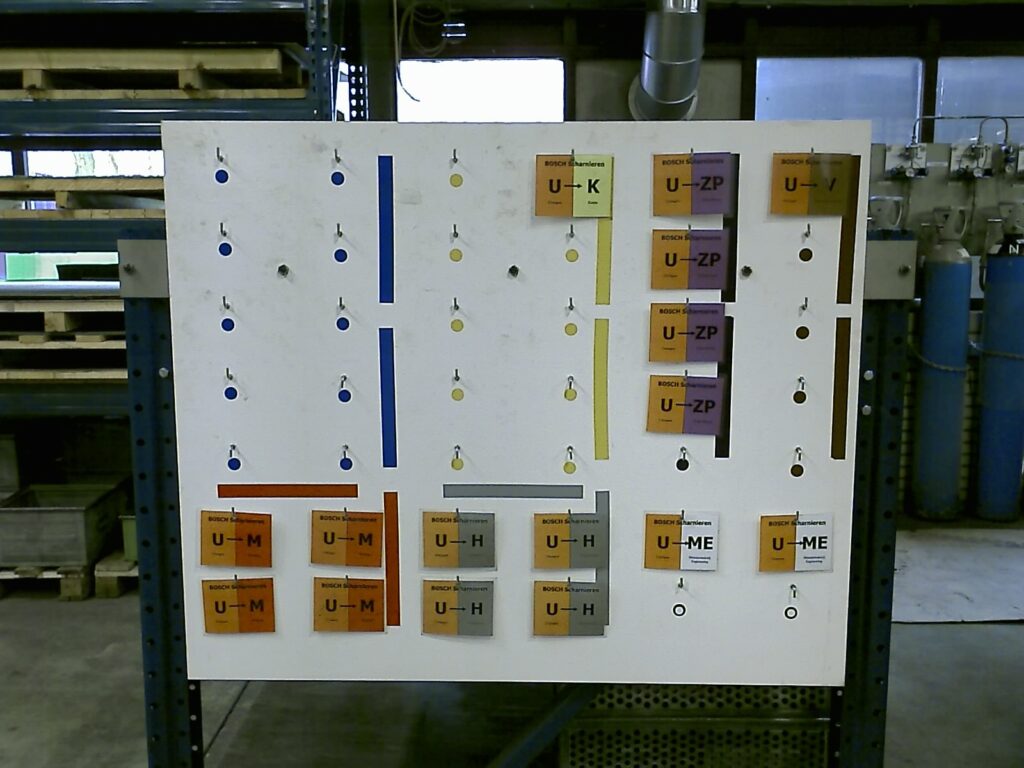

The Dutch company Bosch Scharnieren was the first company in Europe to implement POLCA. Figures 2 and 3 show the Bosch Scharnieren POLCA cards that are attached to an order, and the POLCA board with cards.

Figure 2. Bosch Scharnieren POLCA cards

Figure 3. Bosch Scharnieren POLCA board

The visual nature of the POLCA board makes it easy to discover downstream bottlenecks. When no cards are available for a specific work station, operators should work on orders that go to other stations. If no cards are available at all, there are various options:

- A first option is to send the operators to the station that forms the bottleneck. By helping their colleagues, they can resolve the blockages to restore smooth flow.

- Another possibility is to use the time available for training, maintenance work, improvements, administration, team meetings, counting stock, etc.

POLCA is thus not just an order guidance system, but also a capacity management system that deploys employees more efficiently, so that operators do not build up unnecessary stock.

Advantages of the POLCA system

Now that we know what POLCA is and exactly how it works, what are the advantages you can expect when you implement the system?

- Limited number of cards

In contrast to the standard Kanban system that works with product-specific cards, the number of cards in POLCA remains manageable, even for increasing product variety. This prevents the stock explosion that can arise with Kanban. - Effective in complex environments

Instead of allocating cards per product variant, POLCA determines the number of card types on the basis of the number of production loops. Consequently a pull system remains effective, even in complex environments with a wide product variety. - Can easily reduce lead time

A POLCA system limits the Work In Process (WIP) on the shopfloor by regulating the number of cards. Shortening the lead time therefore becomes easier: a few POLCA cards are simply removed, and the WIP and lead time drop! - Better delivery reliability and lower costs

Moreover, companies that have implemented POLCA experience improved delivery reliability because employees focus on the right tasks. In addition, POLCA leads to more efficient use of production capacity and lower indirect costs because planning and management become less complex.

Give POLCA a chance: standard or digital

Now that you understand the basis of POLCA, it’s relatively easy to implement it yourself. A few laminated cards and a POLCA board already make the advantages clear, to your production employees too. If everyone is aware of the system, the way it works and the advantages, the chance of success is greatest.

There are also various digital POLCA systems that make use of physical cards unnecessary. Therefore the cards need not be returned and cannot be lost. Commercial digital POLCA systems are currently being sold by 24flow (Belgium), PROPOS Software (Netherlands) and Axxalon (Germany).

Do you make many different products in small volumes and do you want to be able to respond to customer queries faster? Then QRM (Quick Response Manufacturing) offers a number of solutions. Register via the link below for our 10-part training course to learn all about this principle, from theory to implementation and more.