How to reduce delays and satisfy customers more? DIAM adopts the QRM-method!

By Quick Response Enterprise – France

The DIAM Group creates, develops, produces and installs a wide range of merchandising solutions (POS) and sales solutions to enhance in-store products. Their services are aimed primarily at major luxury brands. For more than 40 years, DIAM has been supporting its customers around the world and deploying treasures of the imagination, to create an effective and unique consumer experience. To reduce delays, (the key topic of customer satisfaction and performance) from the start of the customers project to delivery, DIAM has conducted many substantive actions and adopted the methodology of QRM (Quick Response Manufacturing) to support these actions.

Demanding customers, a fast-evolving market and an industry with speed

In the market of point-of-sale, speed is essential and projects are complex, brands like to react quickly to the trends and innovations induced by the ever-changing consumer need. Due to this, retail needs to be increasingly more innovative. Marketing and merchandising often change their needs during projects and the products are never the same. No production in series, always development of specific products with a lot of creation and yet a strong need for industrialization for economical and speed reasons. Our customers need to adapt to a market that is changing very quickly and continuously, because the competition is tough. The best way to assist them is to help meet their deadlines and reduce them, for permanent materials as for ephemeral products.

Françoise Raoul Duval, DG Prestige Europe, shares her testimony on an adventure that started in 2015. The reduction of deadlines, from the start of the client project (tender for a new product), until delivery (products in stock or in stores), is therefore a key issue for DIAM. Both to satisfy customers’ needs (therefore continuing the growth of sales) and to improve internal operations. Their 20 years of experience in the industry has proven that reducing lead times is also the best way to optimize your performance, as it requires you to always ask questions of yourself. To do better and to create secure plans.

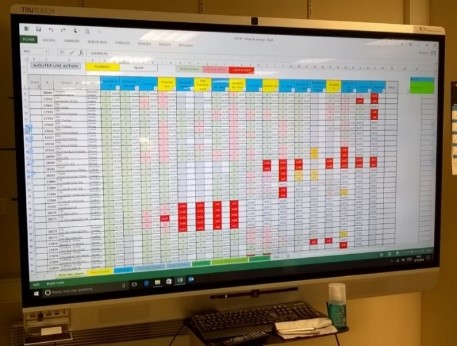

Daily management of business around an interactive chart. Allowing the project collective to manage the milestones and improve communication.

The QRM method: A competitive advantage for small series and multi-variant products

There are several ways to reduce delays. The QRM-method is certainly the most suitable for their business of POS, as it allows them to manufacture in small series and it adapts to environments with no existing standard products. After the launch at the end of 2015, time reduction projects with a reduction target of more than 40% were met. The method proved to be very adaptable to their needs; to reduce lead time from order to delivery, whilst respecting the peculiarities of the market (complex projects and shorter deadlines). QRM has allowed them to do better, satisfy their customers (reduction of deadlines) and accelerate the development of sales in a significant way. Whilst simultaneaously simplifying DIAM’s organization and thinning out the operations. The method does not exist as a dogma, it is an accompaniment for important changes. It provides a strategic framework and operational structure, strongly boosting the teams with one common goal: releasing the energy to explore and experiment with different functions.

To succeed in lead time reduction projects, DIAM have mobilized key managers and operational staff on a project management perimeter from A to Z. From the expression of the client brief to the delivery of the order. They started with simple diagnoses to measure the projects ‘Time of Passage’ (the projects flow of time in calendar days) and identifying ‘unnecessary time loss’, seen from the client’s point of view. Moments without any value adding activities; such as prognosing, multiple round trips between operations, corrections and modifications are what we call the ‘White Areas’ or ‘White Spots’ in QRM-language.

Within most of their business, they have identified over 70% of ‘lost time’. As a result, ideas for reducing lead times have rocketed, with a strong mobilization of transversal functions and great examples of teamwork. Accepting the questions asked of the current operation and daring to experiment with simpler and more fluid alternative operations has allowed the QRM methodology to readress and resolve organizational issues. The “who does what”, in describing the operational activities of a case and to note the nature of the disturbances of the flow of a case in the operation. This is called “pebbles in the shoe”. This process allowed DIAM to share all the constraints of launching business: strategic purchasing, development, tools and production workshops as well as redefining the roles of the company’s central functions. Always working from a customer perspective, value adding and creating speed. To identify and prioritize the opportunities, in order to reduce the white areas.

Finally, teamwork enabled them to identify gaps in skills, which they still fill in certain functions today, because the roles are clarified and the requirements are stronger.

QRM is not about working faster, but working better together!

The implementation of the QRM-approach has resulted in a significant delay reduction of more than 30% on average, in cases that last from 2 to 6 months and cost reductions around 10%. This is dependent on the factory and induced by a simpler and more fluid operation. Beyond these convincing results, the QRM-workshops and objectives made it possible to mobilize and work better together. This leads to strengthening collaborative work, improving communication between the teams and trusting each other on a case and above all, a better understanding of the issues involved. The customer needs are the collective approach of steering business milestones and reducing white areas, benefiting both the customer and each worker in the company. This leads to less disruption, simpler communication circuits and a better first shot of things. The time won can be reinvested in development and technical innovations. The QRM-method has largely contributed to the recovery of customer satisfaction and DIAM’s results.

Key factors in the success of a QRM

As in any process of transformation, first and foremost, the commitment and involvement of the management are the first key factors to success. Thanks to the teams, a new, simpler and more fluid operation is being formed. Transformations are rarely simple and meet resistance, it requires determination and consistency. QRM is common sense; a pragmatic spirit (no dogma, unlike other methods) and the simplicity of the method are its major assets. The reduction of lead times goes through the rigor of a mastered process, adapted tools and a visual management, especially by working better together. The strong support and the expertise of QRE (Quick Response Enterprise), who accompanied DIAM, in animating and facilitating a collaborative dynamic within the teams, was essential in the frst year. Then another year to involve the clients and suppliers more in the process.

The first results arrived quickly and it is ever so important to also celebrate the small victories. This creates the credibility and the virtuous loop of the results. It is the workers who create these results, not the methods and it must always be emphasized; even if the method is essential to the start-up, as are strategic directions. In the end, and for the process to last, it is up to the workers of DIAM. The method provides the necessary framework and dynamic impulse, but it is the teams who make the change and take ownership of this new agile operation.